Knif Quality

Knif has chosen specific common components to achieve the company value of providing only the highest quality products, this includes:

PRECISION AND LONGEVITY

ELMA® rotary switches are used throughout for precision, easy recall, and longevity. Potentiometers are only used where continuous adjustment range is required. For the sake of serviceability, we refuse to place more than two switches on a single PCB.

LONGLIFE DIALS

Engraved front and rear panels with color infill ensure a virtually indefinite lifetime of the dials.

REFERENCE CONSTRUCTION

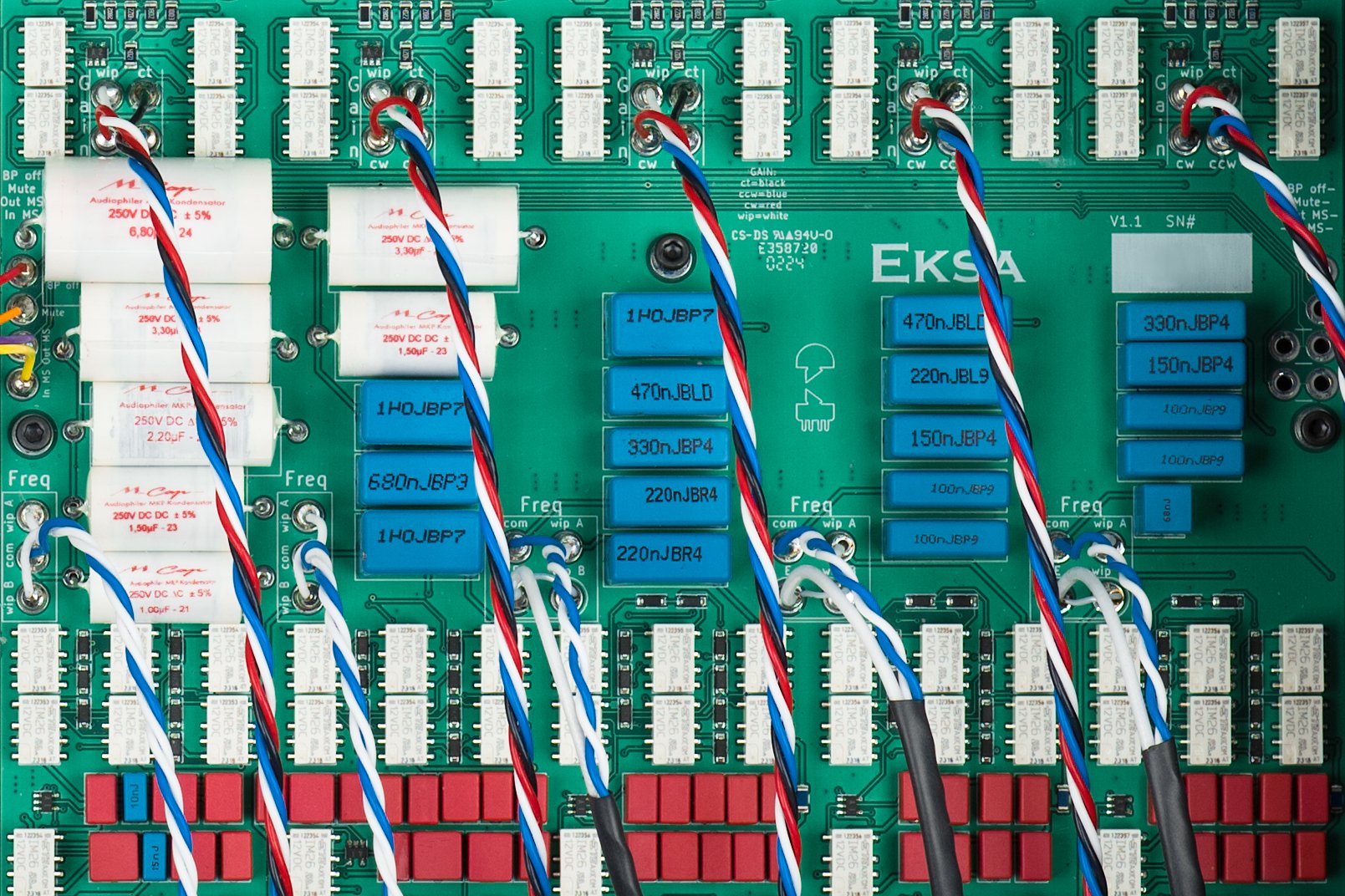

Thick main PCBs (2.4 mm vs standard 1.6 mm) with 2 oz copper and PTFE insulated silver plated copper wire are used throughout.

DOWN TO THE FINEST DETAIL

High quality SMD components – thin film resistors and NP0/G0G capacitors are utilized throughout.

ULTIMATE TRANSPARENCY

Polypropylene capacitors from Mundorf®, Wima® and Kemet® provide the purest audio path possible. Capacitors in critical locations are always matched for perfect channel balance.

HEAVYWEIGHT MECHANICS

CNC-machined anodized heavy gauge aluminum chassis builds the foundation, and the 10 mm thick side panels provide means for sufficient heat dissipation and distribution.

PERPETUAL CONTACT

All signal connectivity uses gold-plated Neutrik XLR-connectors for trouble free long-term operation. In Knif gear, internal signal routing is always free of connectors.

HERMETIC SWITCHING

Signal switching on the PCB is executed by relays with gold-plated contacts and a mechanical lifetime expectation of no less than one hundred million operations.